Key Points

- An Ausbeulstation is a dedicated professional workstation for repairing dents in car body panels, often using paintless techniques to restore shape without refinishing.

- It delivers major efficiency gains for workshops by shortening repair cycles, cutting material costs, and improving finish quality.

- Research and industry sources suggest it preserves vehicle value, boosts profitability, and handles both steel and aluminum panels effectively, though results depend on tool quality and technician skill.

- No major controversies exist, but debates focus on PDR vs. traditional methods for severe damage—evidence leans toward Ausbeulstation for minor to moderate dents.

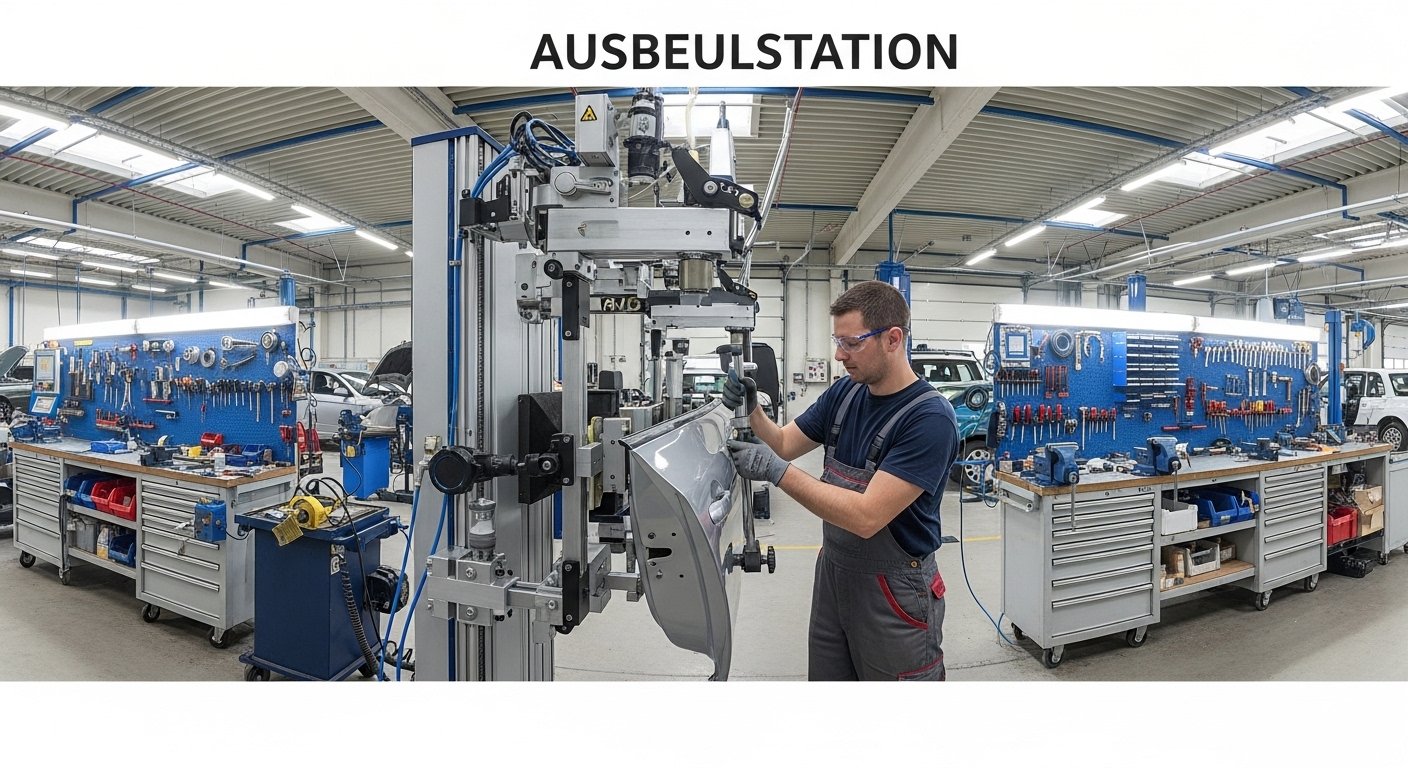

What is an Ausbeulstation? An Ausbeulstation (dent removal station) serves as a centralized hub for precise dent correction on vehicle sheet metal. It combines specialized tools to pull or push dents back into shape, minimizing or eliminating the need for body filler and repainting.

Core Benefits: Workshops see faster turnaround times, reduced labor, and higher margins. Customers appreciate quicker repairs with factory-like finishes.

How to Get Started: Choose a setup based on your typical jobs (steel vs. aluminum), space, and budget. Start with training to master techniques for consistent results.

Supporting Resources

- Manufacturer sites like Telwin and GYS for equipment specs.

- Guides on PDR techniques from industry blogs.

Professional Ausbeulstation setups represent a cornerstone of modern Karosserie-Instandsetzung (body repair), especially for technicians focused on efficiency and quality in Kfz-Reparaturset tasks. In a busy shop, time is money, and a well-equipped Ausbeulstation turns hours of traditional work into streamlined processes that preserve paint, maintain structural integrity, and keep customers returning.

Picture this: a hail-damaged vehicle rolls in on a busy Monday. Instead of booking days in the paint booth, your technician assesses the panel, selects the right tool from the station, and completes most repairs by end of day. The finish looks factory-fresh because the original paint stayed intact. That scenario happens daily in shops using a quality Ausbeulstation.

An Ausbeulstation is a specialized workstation designed for Blechbearbeitung (sheet metal working) and dent removal. It centralizes tools for controlled force application to correct dents, creases, and hail damage. The German term highlights its popularity in European workshops, but the concept aligns with global paintless dent repair (PDR) and dent pulling systems. Modern versions handle steel, aluminum, and sometimes composites, using welding, pulling, pushing, and heat management to restore panels without distortion.

A complete setup includes:

- Punktschweißgerät / Spotter (Stud Welder): Attaches studs or tabs to the dent for pulling. Modern units offer multiple modes for steel and aluminum, with digital controls to avoid burn-through.

- Zughammer / Pull Hammer and Gleithammer (Slide Hammer): Deliver controlled impacts or steady pulls to lift dents.

- Dellendrücker / PDR Tools: Rods, hooks, and picks for pushing from behind panels when access allows.

- Glue Pulling Systems: Tabs, hot glue guns, lifters for external pulling on inaccessible areas.

- Lighting and Diagnostics: LED reflection boards and paint thickness gauges to read panel contours accurately.

- Heating Tools: Induction heaters or heat guns to relax metal and prevent cracking.

- Support Accessories: Werkstattwagen (tool cart) for mobility, clamps, safety gear, and consumables like glue sticks and release agents.

Many complete kits come on mobile carts for flexibility across bays.

Investing in a profi Ausbeulstation brings clear advantages:

- Faster Cycle Times: Central organization cuts setup and movement, often finishing minor jobs in hours instead of days.

- Higher Profit Margins: Less filler, primer, and paint time reduces material costs; premium PDR rates increase revenue.

- Superior Quality: Original paint stays intact for better corrosion protection and factory appearance, leading to satisfied customers and positive reviews.

- Versatility: Handles steel for robust pulls and aluminum with gentle settings to avoid stretching.

- Scalability: Mobile versions allow quick response to hail events or multi-vehicle repairs.

In practice, shops report noticeable productivity jumps after adopting these systems, especially when paired with technician training.

The process follows a logical sequence:

- Assess the Damage: Use lighting to read crowns, lows, and tension lines on the panel.

- Choose Technique: Access from behind? Use PDR rods. Limited access? Glue tabs or weld studs.

- Attach and Pull/Push: Weld studs securely, then apply incremental force with a Zughammer or slide hammer. Combine with gentle tapping or heat to relieve stress.

- Refine and Finish: Knock down highs, check reflections, remove attachments, and polish.

Heat management proves critical—too much risks paint damage; controlled application softens metal safely.

Consider these factors:

- Vehicle Types: Prioritize aluminum-capable units if you service newer models.

- Volume and Space: Mobile carts suit smaller shops; fixed stations fit high-volume ones.

- Budget vs. Features: Entry-level spotters work for basics; pro models with auto-adjust and high power deliver consistency.

- Brands: Look at reliable names like STAHLWERK, GYS, Telwin, or Pro-Spot for durable builds and support.

A good starting point is a combo set with spotter, pullers, and accessories for steel and aluminum.

Steel allows stronger welds and higher pull forces for deep dents. Aluminum requires lower power and precise timing to prevent overheating or weakening. Many modern stations include dual modes or specific aluminum kits to handle both seamlessly.

Practical Tips for Maximum Efficiency

- Train regularly—PDR skills improve with practice.

- Maintain tools—clean tips, check cables, store organized.

- Use reflection lines religiously to avoid over-pulling.

- Combine techniques (glue + push) for complex dents.

- Track jobs to refine pricing and workflow.

Comparison Table: Traditional vs. Ausbeulstation Repair

| Aspect | Traditional Repair | Ausbeulstation Approach |

|---|---|---|

| Repair Time | Days (filler, sanding, painting) | Hours for most dents |

| Material Costs | High (filler, primer, paint) | Low (minimal consumables) |

| Paint Preservation | Rarely | Often 100% |

| Finish Quality | Good, but not factory | Factory-like |

| Structural Impact | Possible distortion | Minimal |

| Profit Potential | Moderate | Higher due to speed and rates |

This table highlights why many shops transition to dedicated stations.

In summary, a professional Ausbeulstation transforms dent repair from a bottleneck into a profit center. It streamlines Karosserie-Instandsetzung, improves outcomes, and positions your workshop as efficient and modern. Start by evaluating your current workflow and exploring complete sets that match your needs.

- Assess your dent volume and materials (steel/aluminum).

- Research mobile or fixed Ausbeulstation options with dual capability.

- Invest in training and pilot a few jobs to measure time savings.

You May Also Like: Your Safe & Savvy Guide to Using Craigslist NH

Q: Can beginners use an Ausbeulstation effectively?

A: Yes, with training. Start with basic glue pulling before advancing to stud welding.

Q: Is it worth it for small shops?

A: Absolutely—mobile versions offer flexibility without huge space needs and pay off quickly through faster jobs.

Q: Does it work on aluminum panels?

A: Modern units do, but require specific settings to avoid damage.

Q: How long does a typical repair take?

A: Minor dents often finish in 1-3 hours; larger ones may take a day.

Q: What maintenance is needed?

A: Regular cleaning of welding tips, cable checks, and organized storage extend life.

Q: Can it handle hail damage?

A: Yes, especially with good lighting and multiple tools for numerous small dents.

Q: Where can I buy a complete set?

A: Check suppliers like Telwin, GYS, or specialized Karosserie tool sites for pro kits.